- TOP

- Special Program by Organizer

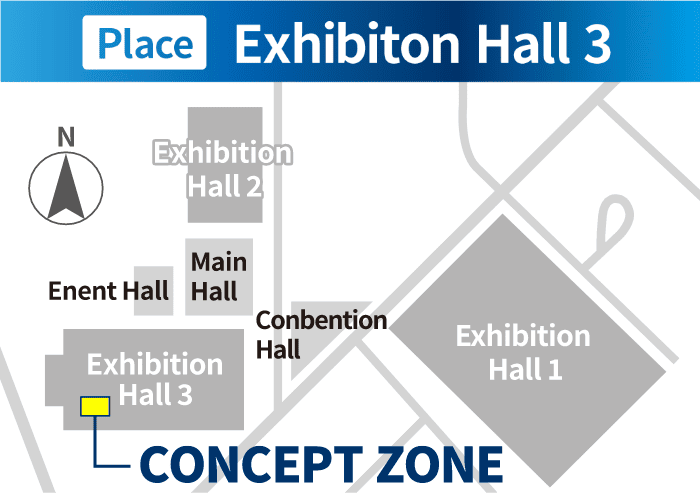

Medical care, along with aerospace and energy, has long attracted attention as a next-generation industry. The medical equipment market in Japan has been steadily expanding and is expected to grow further in the future as the aging of society progresses and medical field becomes more advanced. With their advantages in terms of high accuracy, complex machining, miniaturization, automation, and other areas, how should Japanese companies respond to market needs in the medical field with the technologies they have cultivated so far?

Under a theme of “Processing Techniques Supporting the Medical Field,” we will showcase processing techniques of three companies with advanced technologies at the venue and explore new possibilities.

Live Machining of Three Types of Medical Parts at the Venue!

Not just displaying finished workpieces — three actual machine tools will be set in the zone for live machining demonstrations.

Don’t miss the chance to experience the latest machining know-how up close— machine motion, cutting sounds, and setup techniques —all on-site!

CooperationCASTEM/

ROKU-ROKU SMART

TECHNOLOGY

TECHNOLOGY「AndroidⅢ」

This exhibit features a palm-sized replica of forceps used in laparoscopic surgery. The parts are fabricated by metal injection molding (MIM), and the movable parts of the product can be moved just like those of the actual instrument. On display at the venue will be the fine processing technology used for the mold part with the most intricate shape (knurl pattern on the claws on the tips of the forceps) among the multiple components fabricated by the MIM production method.

Metal injection molding (MIM): A technology for producing metal products by mixing metal powders and binders, shaping the mixture through injection molding, and finally sintering it.

Knurl pattern: A fine, uneven surface texture applied to metal parts to improve grip and prevent slipping.

Seminar / Demonstration Time

| 22th,23th | 10:30~ / 13:00~ / 15:00~ |

|---|---|

| 24th | 10:30~ / 12:30~ / 15:00~ |

| 25th | 10:30~ / 13:30~ |

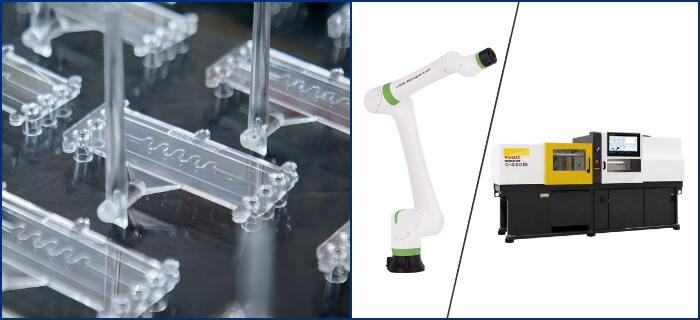

CooperationSAYAMA MOLD

MANUFACTURING/

FANUC

ROBOSHOT α-SiB」

Microchannels are essential for microphysiological systems (MPS) that are attracting attention in drug discovery and medical settings. High-precision processing of complex shapes—such as mirror finishing of molds used to create microchannels and mold structures that enable gate cutting in injection molding machines —is craftsmanship achievable only by mold manufacturers with advanced technical expertise. At the venue, an automation process that enables unmanned molding production will be exhibited, along with a manufacturing process that reduces costs through labor savings, shortens lead times, and constantly supplies stable quality.

MPS: Microphysiological System

Seminar / Demonstration Time

| 22th,23th | 11:00~ / 13:30~ / 15:30~ |

|---|---|

| 24th | 11:00~ / 13:00~ / 15:30~ |

| 25th | 11:00~ / 14:00~ |

CooperationMEIRA/

NAKAMURA-TOME PRECISION

INDUSTRY

INDUSTRY「MX-100」

Titanium alloys (difficult-to-machine materials) with high biocompatibility are commonly used for orthopedic implants to avoid adverse effects on the human body. These implants are designed based on the human skeletal structure, and this requires complicated shapes and a high degree of accuracy. A MECT-original workpiece has been specially designed with a complex shape resembling an orthopedic implant. The new processing method utilizing the features of a multi-tasking machine to process multiple workpieces from the same material in integrated production, from the material to the finished shape, is a must-see.

Seminar / Demonstration Time

| 22th,23th | 11:30~ / 14:00~ / 16:00~ |

|---|---|

| 24th | 11:30~ / 13:30~ / 16:00~ |

| 25th | 11:30~ / 14:30~ |

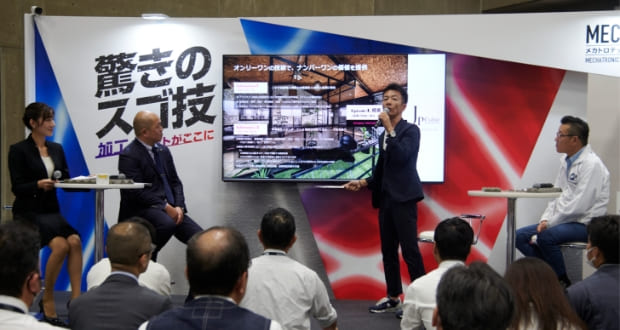

This seminar features three Concept Zone partner companies that continue to play an active role in the medical field. As medical equipment and instruments become smaller, more complex, and more accurate, these companies will share their strength, keys to success, and future strategies in an in-depth discussion.

No reservation is required.Please come directly to the venue.

Seminar details may change or be cancelled without notice

| Date | Friday, 24 October |

|---|---|

| Time | 14:00~14:45 |

| Place | Special Stage in Concept Zone |